PretensT

Tensegrity is a special kind of structure made of push and pull.

Project maintained by elastic-interval Hosted on GitHub Pages — Theme by mattgraham

The Perception Gap

The hard part about getting across the idea of tensegrity is that talking about it, and even showing pictures or movies, just isn’t enough to make the intuition take hold.

Sure, it’s possible to make a nice website that visually catches someone’s interest, but in reality they will only be able to scratch the surface.

It’s something you need to feel. The only way is to get tensegrity into peoples’ hands!

So I set about finding a way to refine the building process for replication, so that I could build enough robust pretenst structures that I could ship them to people.

Prefab tension

The lessons learned along my journey from building the first structures to nearly automating the production were all progressions from my starting point of prefabricated tension.

That is to say tension connected while slack, and this allowed high-performance materials to be used, like Dyneema cord which is extremely strong and almost inelastic.

This strategy implies that the compression necessarily needs to be extensible, and since it has become the source of tightening, it needed to extend by turning a nut on a bolt to have enough strength.

Experience taught me that it was an extremely important consequence of this strategy was that it enables loosening the structure when it needs to be fixed, and that happens. Afterwards, it can be tightented up again.

Another consequence is that tensegrities can be easily re-tightened as the materials and the connections get accustomed to high tension.

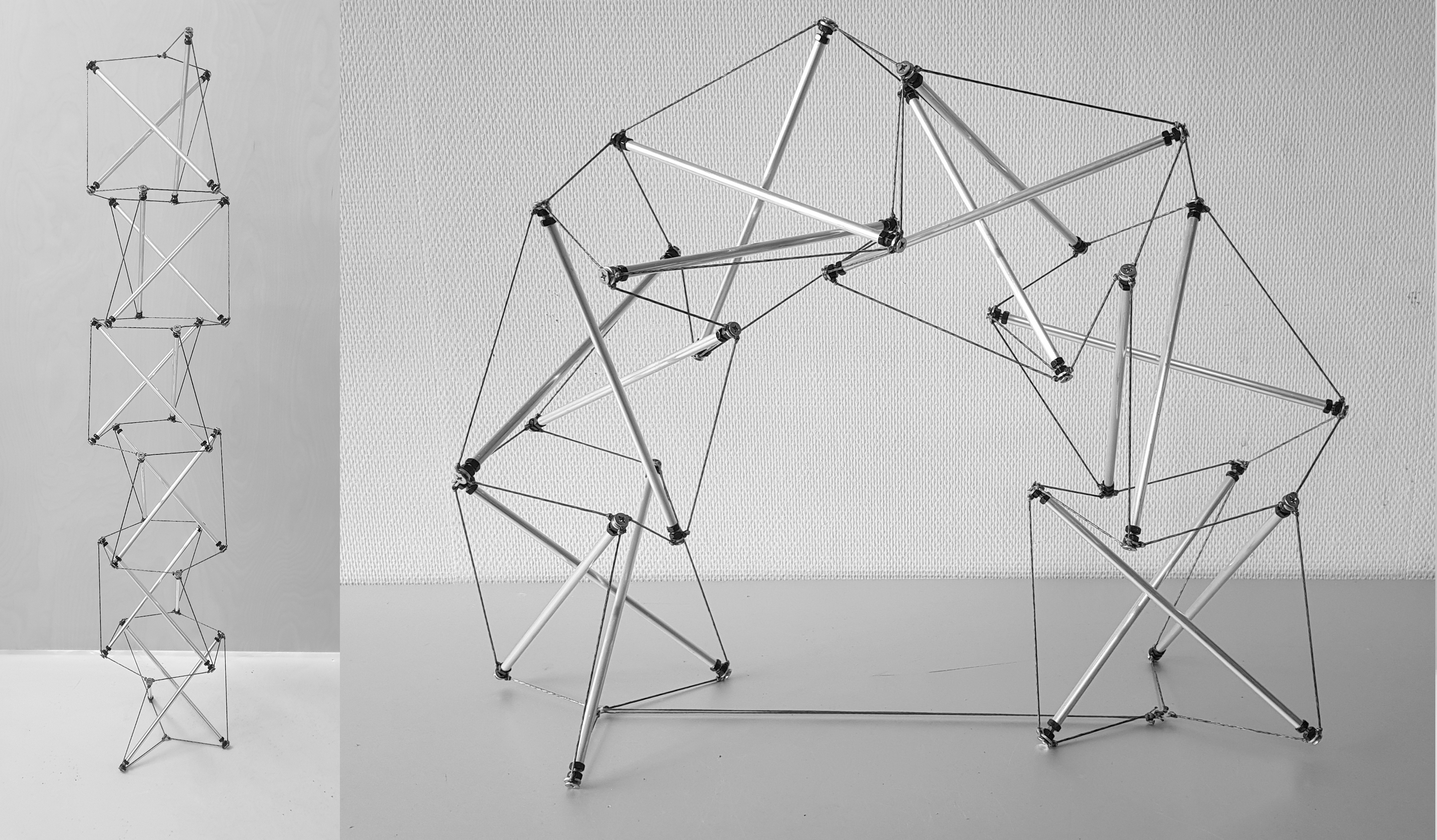

Minimal

It also took quite some time and experimentation before I arrived at the right kind of structure, which is the minimal one.

Minimal in the sense that every segment of cord is participating at all times, so nothing is ever actually slack. There are no redundant cords.

The resulting structure exhibits a special kind of flexibility when very tight, which few have grasped (pun intended) but I believe fundamental to understanding tensegrity.

This minimal structure is the natural baseline, but if you want to give a tensegrity a particular shape or purpose, it makes sense to add tension lines where needed.

Wrench adjustable

We can reach a whole new level of tension when we are able to tighten a tensegrity up with a wrench!

Most adjustments can be done by hand, depending on what the goal is, but the option of taking it to much higher levels by turning nuts allows a minimal tensegrity to stand straight as a tower.

Turning nuts tight is not the only way to tighten this tensegrity, but the other way involves (paradoxically) first loosening the nuts, so the whole tensegrity goes limp.

The limpcolumn can then be arched to once again become highly tensioned in a new way.

Replication

It had to get a lot easier to build this structure than the ones I have built so far! I need to have almost a production line, if I want to get more hands to see.

Ultimately I was able to come up with a way to build it which didn’t require any fabricating of joint parts, because they were all off-the-shelf (or at least already manufactured and available online). I even ordered the bars pre-cut to the 25cm length that was just right.

The only challenge to overcome was the manufacture of large numbers of Dyneema cord segments which could be connected together to make the tension network.

For segmentation I came up with a trick to wrap the cord around a perfectly sized core many times and then cut it from end to end perpendicular to the cords. Each one still needed the blowtorch treatment, which is now the slowest part of the process.

I then taught myself how to construct the six twist essential tensegrity as quickly as possible from start to finish.

Deflation-Reflation

Not only did we need to be able to build these structures in larger numbers, we also needed to be able to pack them up for shipping somehow.

Fortunately the starting point can be the limp tensegrity, already fully connected, but even that structure becomes tight and expands when it is bent.

We needed to be able to pack it up so that people could re-construct it, but this had to somehow become simple enough that anybody could do it without more than a few instructions.

After much trial and error, we devised a technique which temporarily replaced one bar of each twist with what is effectively a very short bar.

This way the whole structure folded up very nicely indeed!

Conclusion

I can get high tension adjustable tensegrity structures into other peoples’ hands.

You can finally get yours now.

It’s very exciting to be able to help more people cross the perception gap and hopefully help other people develop new intuitions!

Projects:

2024-07-23: "Bouncy Wooden Sphere": what you can do with a discarded bed2024-04-23: "Twisted Torque": tied into a permanent twist

2023-03-27: "Easy 30-Push Sphere": one simple element

2022-10-05: "Glass and LED": going big and colorful

2022-09-29: "Fascia": dancing with tensegrity

2022-08-30: "Mitosis": the four-three-two tensegrity

2022-08-04: "Push Bolts for the People": finalizing design and getting it out there

2022-06-22: "Head to Head Push Bolt": M5 and M6 bolts symbiosis

2022-05-30: "Hiding Knots": bump up the aesthetics

2022-05-25: "Innovation with 3D Printer": the push bolt

2021-12-02: "Headless Hug": breaking a rule for the sake of symmetry

2021-10-28: "Rebuilding the Halo": finally got it right

2021-10-20: "Convergence": growing and reconnecting

2021-07-27: "120-Strut Brass Bubble": taking the next step up in complexity

2021-05-26: "30-Strut Brass Bubble": bouncing spherical tensegrity

2021-04-08: "Bow Tie Tensegrity": better bend resistance

2021-03-29: "Six Twist Essential": what if more hands could see?!

2021-01-25: "Minimal Tensegrity": no more tension lines than absolutely necessary

2021-01-18: "Degrees of Freedom": first adjustable hybrid tensegrity

2021-01-11: "Fractal Experiment": a tensegrity of tensegrities

2020-12-09: "Axial Tension": pretensing what is already pretenst

2020-11-02: "Halo by Crane - Part 2": the strengthening

2020-10-26: "Halo by Crane - Part 1": assembly complete but strength lacking

2020-10-12: "Brass and Tulips": a tight and strong tensegrity tower

2020-08-10: "Prefab Tension Tower": the tower of eight twists

2020-07-27: "Elastic Bubble": building with elastic ease

2020-07-13: "The Twist Sisters": left-handed and right-handed

2020-07-06: "Radial Tension": Pulling towards the middle

2020-06-22: "Diamond of Tension": Four pulls for every push

2020-06-15: "Prefab Tension": Separating compression from tension