PretensT

Tensegrity is a special kind of structure made of push and pull.

Project maintained by elastic-interval Hosted on GitHub Pages — Theme by mattgraham

Final design

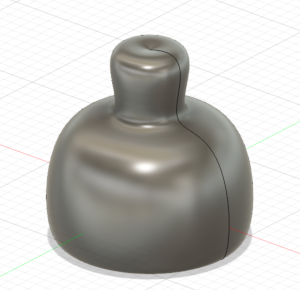

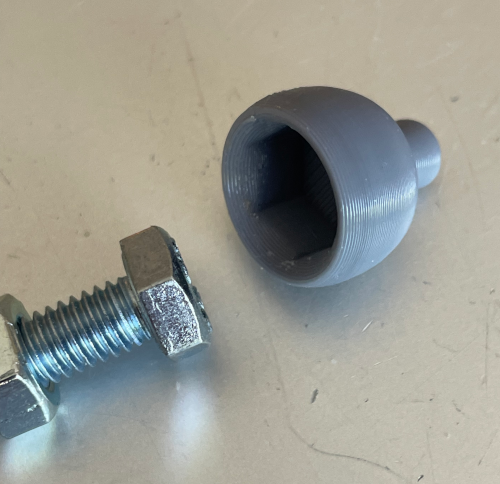

The push bolt designs that I originally tried were functionally exactly what was necessary, but there was definitely still room for improvement.

On the one hand it could be a little prettier and rounder.

On the other hand, I needed to look at getting it to hold very strongly to the bolt head, so it had to go deeper and have thicker walls, and yet it still had to be easy to slip on to the head.

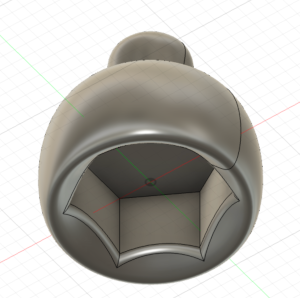

I came up with a nice interplay of curves in the design program, and the result (after a number of iterations, as you may imagine) solved both problems.

This design even has subtle advantages related directly to the 3D printing process, since the “support” that the printer has to build inside the hexagonal hole is quite easy to snap out.

This happens during what I call the “pistachio phase” of the manufacture where I watch a youtube documentary while snapping the scaffold out of each and every push bolt cap.

In the end, the cap can be mounted and stay solidly on top without any glue at all!

I did pick up a tip from the 3D printing world and bought a little 300W hot air gun, because when this PLA gets a little warm it becomes supple and slips on top of the bolt easily, and then it cools it grabs tightly.

Extensible struts

Just put a little hat on the bolts and you get the magic of extensible struts.

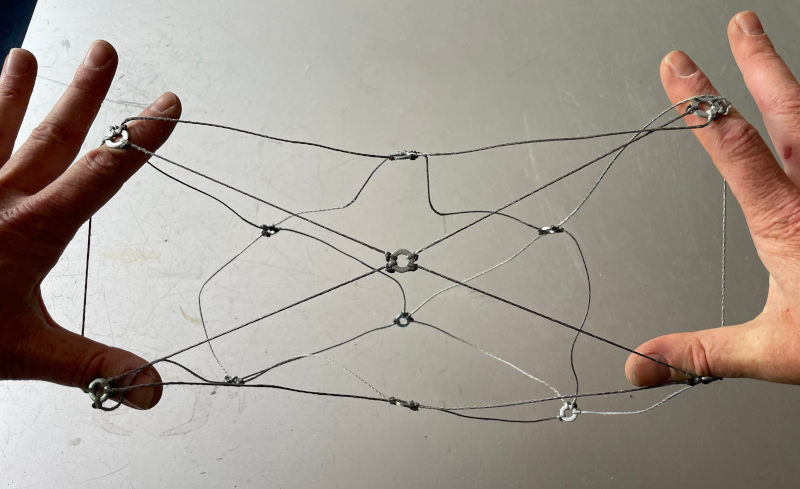

So we can go ahead and get knotty with the rings and cords, assembling the entire tension network while it is totally relaxed and slack.

Then just snap the rings over the nib on the top of the push bolts, and when all the struts are inserted you can tighten up by turning the nut.

New offering: Symmetrical

None of this means all that much if I’m the only person in the world building this way, compared to maybe getting hundreds or thousands of hands doing it.

So I made an instruction video which should be easy enough to follow, especially because you can pause at any time.

The vertebra

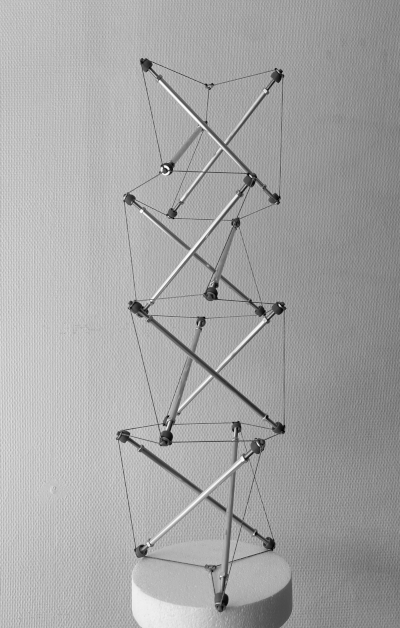

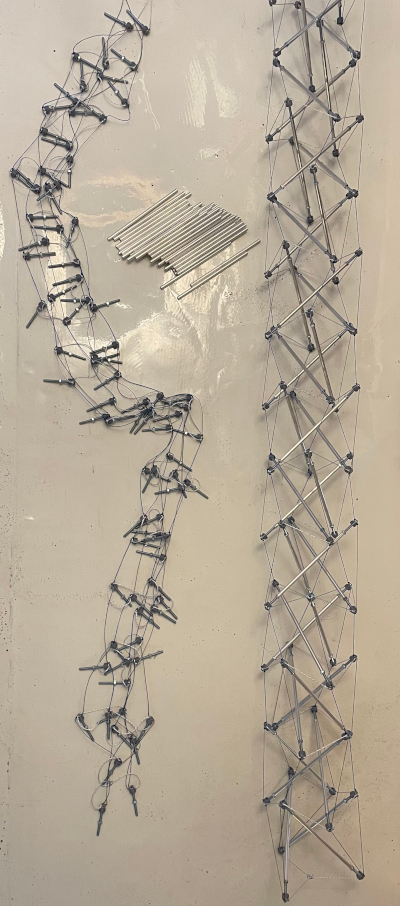

Another kit on offer on offer is the vertebra, which can be connected together in series to make a kind of tensegrity spine.

Here’s how to build with the vertebra:

Out of control

I started building with the vertebra for these movies but with the new push bolt, it has become a very quick robotic routine, so yes I got carried away.

As it turns out, there is a Fascia Research Society conference in September, and I got to talking with May Kesler about building some things for a dance performance at the conference for which she was choreographer and performer.

I built these four towers, each seven foot tall, and booked flights and accommodation for Montréal.

Now I’m looking forward to having as many conversations as possible with people who understand and specialize in fascia, the third holistic network in our bodies (besides nerve net, and blood net), and the one that holds it all together.

Conclusion

Sometimes it’s important to go back to the drawing board (or in this case Fusion 360) and see if some incremental improvements can make a significant difference.

I’m very happy with the new push bolt cap, especially given how much easier and more pleasant it was to build those tall towers.

Best of all, once a tower is built it’s pretty easy to separate the tension from the compression.

Then I can box them up for transport!

Projects:

2024-07-23: "Bouncy Wooden Sphere": what you can do with a discarded bed2024-04-23: "Twisted Torque": tied into a permanent twist

2023-03-27: "Easy 30-Push Sphere": one simple element

2022-10-05: "Glass and LED": going big and colorful

2022-09-29: "Fascia": dancing with tensegrity

2022-08-30: "Mitosis": the four-three-two tensegrity

2022-08-04: "Push Bolts for the People": finalizing design and getting it out there

2022-06-22: "Head to Head Push Bolt": M5 and M6 bolts symbiosis

2022-05-30: "Hiding Knots": bump up the aesthetics

2022-05-25: "Innovation with 3D Printer": the push bolt

2021-12-02: "Headless Hug": breaking a rule for the sake of symmetry

2021-10-28: "Rebuilding the Halo": finally got it right

2021-10-20: "Convergence": growing and reconnecting

2021-07-27: "120-Strut Brass Bubble": taking the next step up in complexity

2021-05-26: "30-Strut Brass Bubble": bouncing spherical tensegrity

2021-04-08: "Bow Tie Tensegrity": better bend resistance

2021-03-29: "Six Twist Essential": what if more hands could see?!

2021-01-25: "Minimal Tensegrity": no more tension lines than absolutely necessary

2021-01-18: "Degrees of Freedom": first adjustable hybrid tensegrity

2021-01-11: "Fractal Experiment": a tensegrity of tensegrities

2020-12-09: "Axial Tension": pretensing what is already pretenst

2020-11-02: "Halo by Crane - Part 2": the strengthening

2020-10-26: "Halo by Crane - Part 1": assembly complete but strength lacking

2020-10-12: "Brass and Tulips": a tight and strong tensegrity tower

2020-08-10: "Prefab Tension Tower": the tower of eight twists

2020-07-27: "Elastic Bubble": building with elastic ease

2020-07-13: "The Twist Sisters": left-handed and right-handed

2020-07-06: "Radial Tension": Pulling towards the middle

2020-06-22: "Diamond of Tension": Four pulls for every push

2020-06-15: "Prefab Tension": Separating compression from tension